In the industrial sector, efficiency and reliability are critical to maintaining profitability and competitiveness. Power plants, paper mills, steel factories, and food & beverage industries in Bangladesh all rely on complex machinery operating under demanding conditions. Yet, one of the most overlooked aspects of maintaining this equipment is filtration. Whether it is air, oil, or process fluids, proper filtration is the foundation of reliable operations. Without it, contamination leads to premature equipment failure, costly downtime, and reduced efficiency.

Why Filtration Matters

Industrial equipment works in environments where dust, debris, and contaminants are unavoidable. For example:

- Air contamination can clog HVAC systems, reduce compressor performance, and create unsafe working conditions.

- Oil contamination accelerates wear in turbines, hydraulic systems, and engines, drastically reducing their lifespan.

- Poor process filtration can compromise product quality in food & beverage production, paper mills, or chemical plants.

By removing impurities, filters protect machinery, extend service life, and ensure smooth operations.

The Cost of Neglecting Filtration

Ignoring proper filtration results in more than just frequent maintenance—it creates a ripple effect across operations. Contaminated oil can lead to turbine or engine breakdowns, halting power generation and causing nationwide disruptions. In a steel or paper mill, a filtration failure can ruin entire production batches, leading to wasted raw materials and missed delivery deadlines. In competitive sectors, such downtime directly translates to financial loss and damaged client relationships.

Types of Filtration in Industry

- Air Filtration – Ensures clean airflow for compressors, HVAC, and plant environments.

- Oil Filtration – Protects lubrication systems in turbines, generators, and hydraulic machines.

- Industrial Process Filtration – Maintains quality and safety in chemical, paper, and food production lines.

Each type of filtration requires specialized solutions designed to handle unique industrial demands.

Benefits of Reliable Filtration Systems

- Extended Equipment Life – Protects machinery from premature wear and damage.

- Reduced Downtime – Prevents unexpected breakdowns and costly production halts.

- Improved Energy Efficiency – Clean systems run more efficiently, reducing operational costs.

- Product Quality & Compliance – Ensures final products meet both local and international standards.

- Workplace Safety – Cleaner air and fluids create a safer environment for workers.

Real-World Applications in Bangladesh

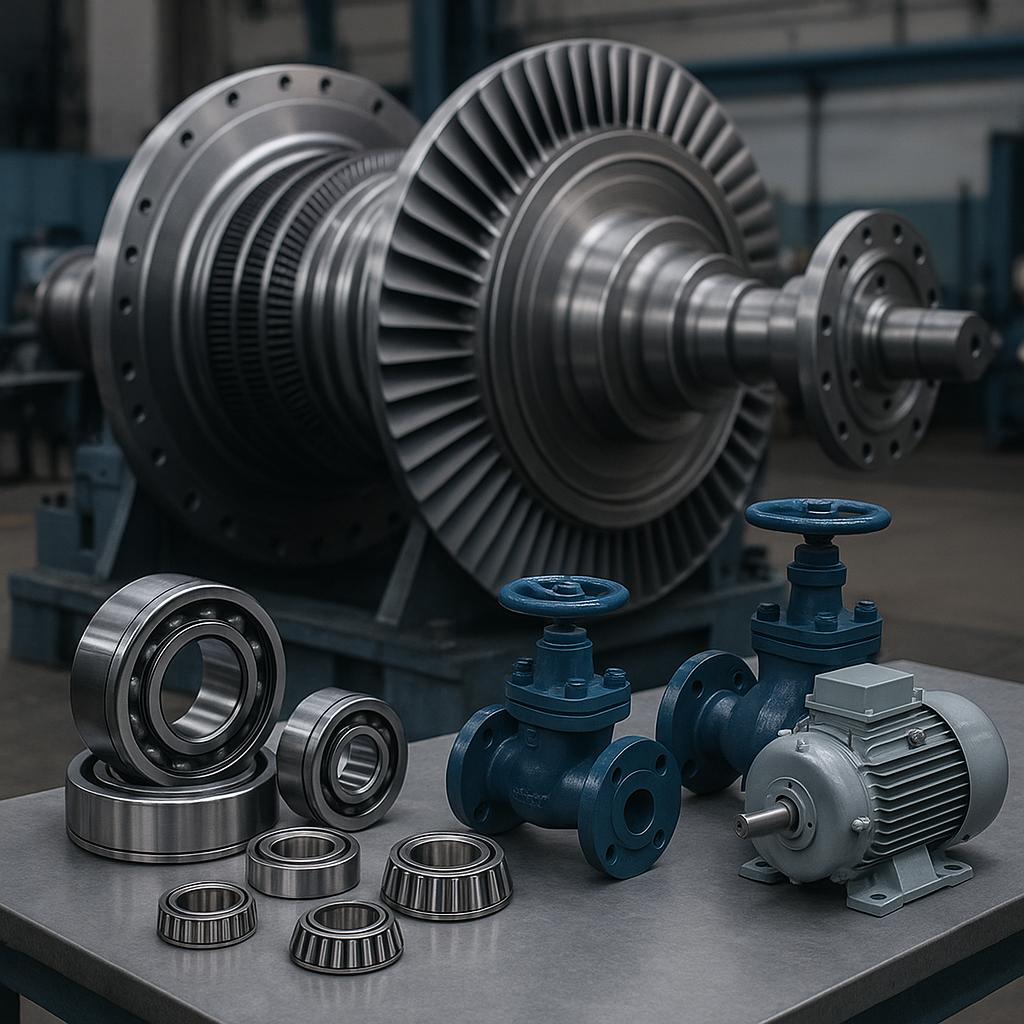

- Power Plants rely on advanced oil and air filters to keep turbines and generators running without interruption.

- Steel Mills depend on filtration to protect cooling systems and ensure consistent product quality.

- Paper Mills require precise filtration systems to reduce waste and maintain smooth production.

- Food & Beverage Factories must use high-grade filters to comply with health and safety standards.

Learn how our Filtration Systems & Consumables are helping Bangladeshi industries protect their assets.

How Tempest Code Delivers Reliable Filtration

Tempest Code supplies filtration solutions from globally recognized brands such as Donaldson, Parker Hannifin, MANN+HUMMEL, and HYDAC. Our offerings cover a wide range of applications, including air filters, oil filters, and complete industrial filtration systems. With our expertise and partnerships, Bangladeshi industries benefit from customized solutions that reduce downtime, improve efficiency, and enhance overall reliability. With our Customized Procurement Services we ensure industries receive the right filters at the right time, tailored to their operational needs.

Conclusion

Filtration may seem like a small part of industrial operations, but its impact is immense. From protecting multi-million-dollar turbines to ensuring food safety, reliable filtration is the key to uninterrupted performance and long-term cost savings. For industries in Bangladesh striving for growth and global competitiveness, investing in high-quality filtration systems is a strategic necessity. Tempest Code stands ready to deliver the solutions needed to keep power plants, factories, and manufacturing units running at their best.